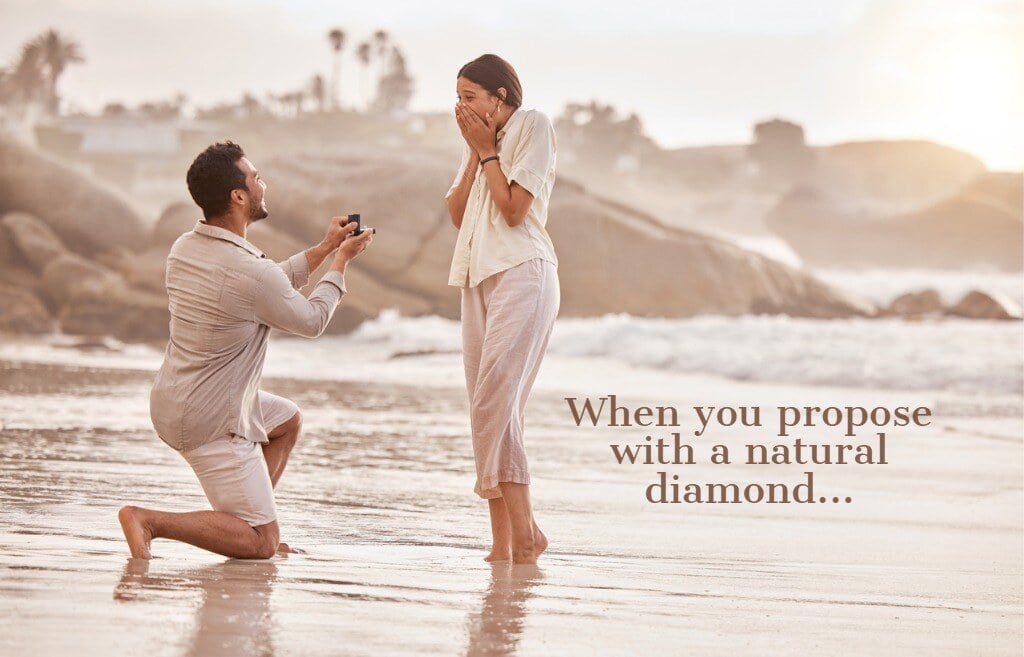

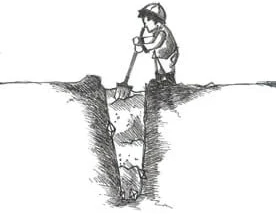

A lot of myth and allure surrounds the true origin of a diamond. Over the years, the industry has come under direct scrutiny over its practices whilst the media coins phrases such as ‘blood diamonds’ and ‘conflict diamonds’ only compounding the negative notions surrounding the sourcing and production of this timeless gem. Unless you’re directly involved in the trade: mining, manufacturing or wholesaling, the reality of a diamond's arduous journey to the consumer's hand is somewhat of a mystery to most. Furthermore, with the popularity of synthetic or lab grown diamonds and diamond simulant alternatives on the rise, it is worth taking a look at how remarkable the journey of a natural diamond truly is. Although one article is not enough to address these issues in detail, I dig deeper by way of a story with hand drawn fun illustrations done by our in-house talented artists to help you discover how long and arduous this extraordinary process is.

Ready to start your journey ?

.jpg)

.jpg)